Precision, repeatability and adherence to global quality benchmarks are critical in the soldering and assembly of modern electronic systems. IPC certification provides a structured, internationally recognised framework that ensures technicians understand and apply the standards necessary for reliable production across sectors such as aerospace, medical devices and defence electronics.

Delivered by a master IPC trainer, this certification is not merely a credential but a demonstration of an individual’s competence, attention to detail and readiness to meet stringent process and inspection requirements that underpin today’s high-performance assemblies.

Understanding IPC Standards and Certifications

IPC, formerly known as the Institute for Interconnecting and Packaging Electronic Circuits, is the global authority on electronic assembly and soldering workmanship standards. Its certifications underpin a significant portion of the electronics manufacturing industry, from original design through to repair and rework. Standards such as IPC-A-610 (Acceptability of Electronic Assemblies), J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies), and IPC-7711/21 (Rework, Modification and Repair of Electronic Assemblies) provide detailed criteria for inspecting, building and modifying electronic assemblies with consistency and precision.

What makes IPC certification particularly valuable is its basis in practical relevance. Each training programme is built around visual inspection guidelines, defect classification, and the ability to make objective, standards-based decisions in real manufacturing environments. These principles are taught through structured electronics training courses that combine theoretical modules with hands-on instruction. For soldering technicians, this ensures not only familiarity with international benchmarks, but the ability to apply them directly to surface mount, through-hole and mixed-technology assemblies. For employers, IPC certification assures a shared language of quality across their teams, supply chain and customer base. Providers such as Advanced Rework Technology bring deep industry expertise to this process, offering tailored instruction that reflects both current standards and real-world production challenges.

The Business Case for IPC Certification

For manufacturers operating in high-reliability sectors, the return on investment in IPC certification is both measurable and strategic. Defect rates, rework time, and customer returns are all closely tied to the consistency and skill of soldering personnel. According to IPC’s own published data, and course descriptions, companies that implement formal training based on standards such as IPC‑A‑610 and J‑STD‑001 report significant improvements in first‑pass yield and a marked reduction in non‑conformances. In industries where downtime carries financial and reputational risk, these improvements translate into lower production costs and higher customer satisfaction.

Beyond operational efficiency, IPC certification supports organisational credibility. When clients and auditors evaluate quality systems, the presence of IPC-trained technicians signals a proactive commitment to workmanship and regulatory alignment. Certification also facilitates onboarding, enabling new hires to adopt established procedures with minimal disruption. For engineering teams, IPC standards form a shared technical framework that improves cross-functional communication, particularly between design, manufacturing and inspection functions. In this context, investing in certified training is not simply a human resource expense, but a quality assurance asset that drives competitive advantage.

Skill Development for Soldering Technicians

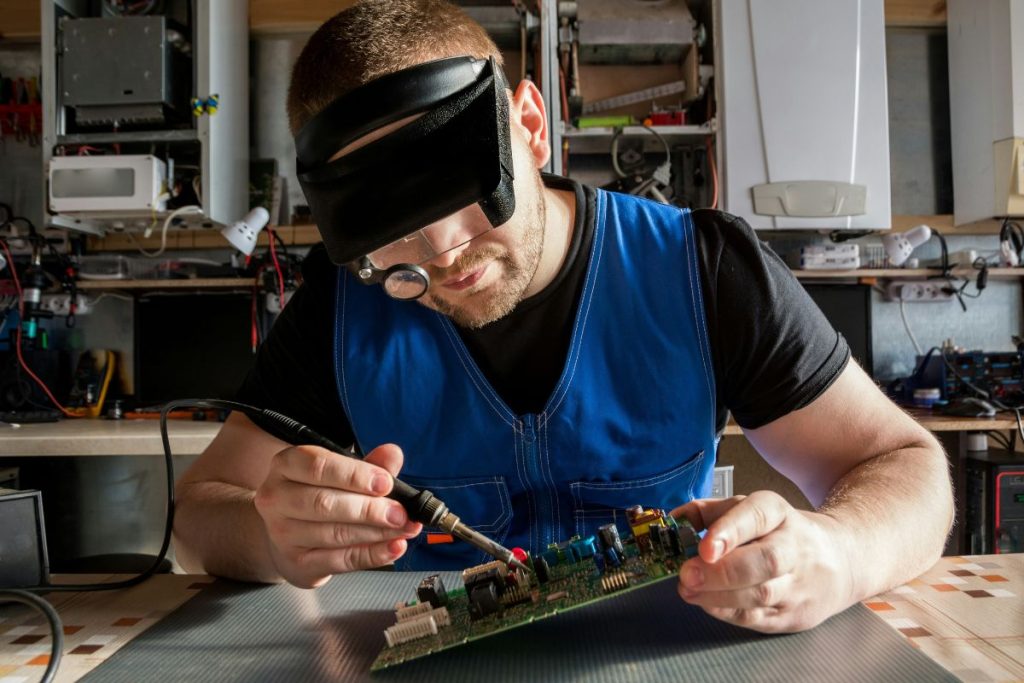

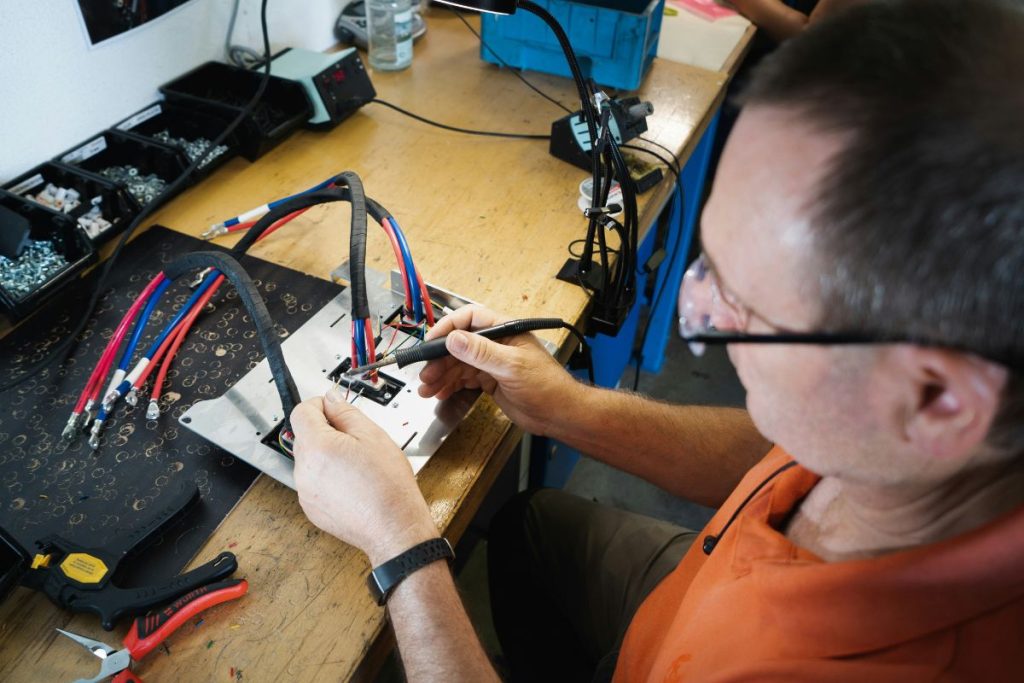

The effectiveness of any electronic assembly process hinges on the capability of the technicians who perform it. IPC certification equips soldering professionals with a structured understanding of component handling, joint formation, thermal management and inspection methodology. Through carefully developed modules, learners are exposed to both the theoretical underpinnings of quality control and the hands-on competencies required to meet Class 1, 2 or 3 criteria, depending on the intended use of the product. This structure ensures technicians are not simply taught how to solder, but why each process step matters in the context of reliability.

Surface mount technology (SMT) and through-hole assembly present different challenges, from the placement of fine-pitch components to managing solder flow in multi-layered boards. IPC training addresses these variances directly, reinforcing proper iron tip selection, dwell time, flux application, and rework limitations. As technicians gain confidence with these variables, they develop the ability to assess their own work against known acceptability criteria. This is critical in fast-paced production environments, where accurate self-inspection and rework decisions help reduce bottlenecks and maintain throughput. For those seeking to elevate their professional standing, certification formalises this skillset and demonstrates readiness to contribute at a higher technical level.

Benefits for Employers and Engineering Teams

Employers benefit from IPC certification through improved consistency, fewer quality issues and stronger team performance. Certified staff are more likely to spot defects early, follow correct processes and reduce the need for rework or inspection bottlenecks. For engineering teams, IPC training creates a shared standard that makes communication clearer and problem-solving faster. It also supports staff development and retention by giving technicians a clear path to grow their skills and contribute more confidently to the wider production process.

Pathways: From Specialist to Master IPC Trainer

IPC certification is not a static achievement but part of a structured progression that supports both individual advancement and institutional resilience. Most soldering professionals begin their journey as Certified IPC Specialists (CIS), focusing on standards application for tasks such as assembly, inspection or rework. From there, technicians may pursue Certified IPC Trainer (CIT) status, enabling them to instruct others and uphold consistent training within their organisation. At the highest tier is the Master IPC Trainer (MIT), responsible for qualifying CITs and maintaining alignment with IPC policy and programme delivery.

This hierarchy ensures that expertise is not only retained but disseminated effectively throughout the supply chain. As technologies evolve and customer demands grow more complex, the ability to deliver in-house, standards-compliant training becomes an operational advantage. In this regard, organisations that invest in CIT and MIT pathways future-proof their capability, reducing reliance on external training cycles and enabling tailored instruction that reflects their products, processes and risk profile. For individuals, moving through these levels represents not only a deepening of technical proficiency but the transition to leadership in knowledge transfer and quality stewardship. It reinforces the view of electronics assembly as a professional discipline with a defined and rewarding trajectory.

Conclusion: Elevating Standards Through Certification

IPC certification continues to play a defining role in the evolution of high-reliability electronics manufacturing. It offers a common framework for quality, a structured path for professional growth and a measurable impact on process outcomes. For technicians, it provides clarity, consistency and the opportunity to contribute with greater precision and confidence. For employers, it strengthens capability, reduces variation and supports long-term operational resilience. As the industry confronts tighter tolerances, complex components and global scrutiny, investing in certified IPC training remains one of the most effective ways to uphold excellence in soldering and assembly at every level.

Images courtesy of unsplash.com and pexels.com and Freepix.com